Data Driven Equipment Replacement Plan

Over the last 7 years or so I have been working on a way to figure out another way to help us determine when equipment needs to be replaced. One that takes the emotion out of the situation and gives you some real data to make decisions by vs just looking at something and saying that it needs to be replaced. I started with a simple excel sheet but as I continued to see other factors that drive replacement I had to make changes, and more changes and so on. Finally I believe I have a working prototype (excel to the max). I utilized the program fully in Dallas and have received a lot of help and feedback along the way building this program. I am currently working on programming it so it can be utilized by the masses online as well as a tool used during my consulting trips to other facilities around the world. Here is an outline of really what it defines:

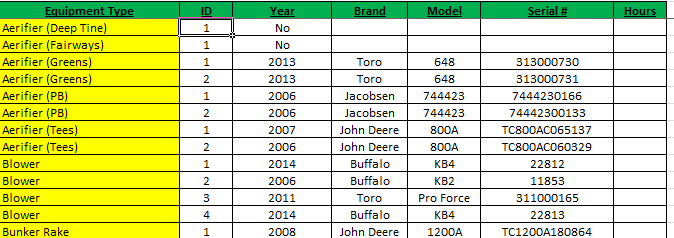

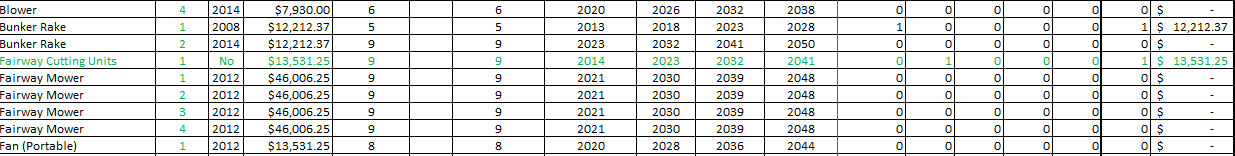

Equipment Inventory

Every golf course should have a complete up to date inventory of their equipment. It should be complete with ID number, Year, Model, Equipment Type, Serial Number, and current hours. You should be updating that list every year. Updating the amount of accumulated hours will help with making your Agronomic Plan more accurate which is a key driver of the 10 year equipment replacement plan.

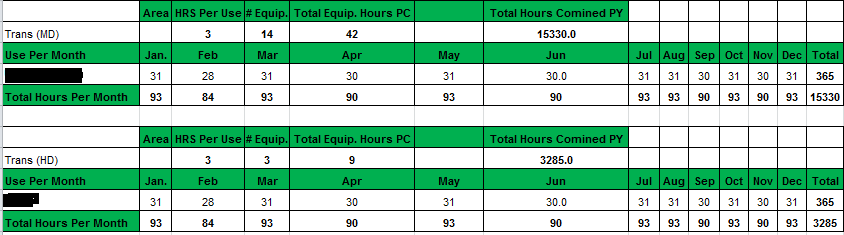

The Agronomic Plan

Everything at your operation should be driven by an agronomic plan. This will determine a lot of things but what I use it for is to tell me how long it takes to do a job task and how many times we will do that task per month. Knowing that will tell me how many hours each month will be put on a piece of equipment. If you know how many hours you will accumulate for a given year you can estimate how many years until you reach a set amount of hours. This is where the program starts. Factual data that is different at every golf course. So when people throw out how long equipment will last and we all assume that time frame should work for us as well it really doesn’t because each facility is unique. Having experienced some consultants in the past they were quick to tell us how they could save us money on equipment but had no data to base the decisions on which resulted in a flawed plan that never would get us out of the hole we were in. That puts us all in a place we don’t want to be at times and so that is the exact reason I felt the formula should be the same but the results ARE going to be different at each facility.

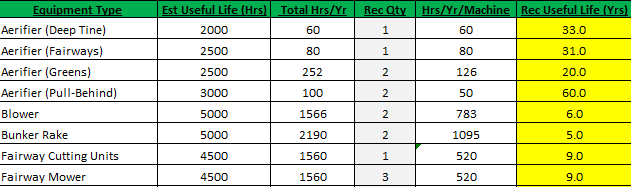

Equipment’s Useful Life

Everything has a useful life. What I mean by this is how many hours are typical for a piece of equipment to last before it starts costing more to maintain it. Each piece of equipment is different and some items may not get tons of hours on it in 15 years and that needs to be thought about. A great example would be a Fairway aerifier. We need them but how many hours per year are we really putting on them? If I told you that most pieces of equipment begin to see a huge decline at around 4500 hours would you believe that to accumulate that at most golf courses on a fairway aerator that could take 20-30 years! If you were to put 4500 hours on it in 5 years it could take it but in a span of 20 not so much due to parts rusting and the machine sitting for months before use. So repairs add up each year mainly because the machine isn’t used much. So one of the things you can do to get started with your 10 year plan is use your agronomic plan to tell you how many years it will take you to accumulate lets say 4500 hours. If you know you will put 1000 hours per year on a rough mower and your useful life is 4500 hours it will take 4.5 years until it needs to be replaced. You do that for your entire fleet of equipment. This can also help you determine if you should lease or purchase equipment.

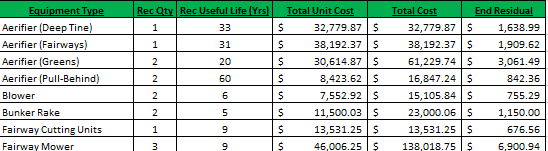

Residual Value

One of the common questions I get lately is about residual value. I look at this 2 ways. Residual value on a lease is what the estimated value will be on your piece of equipment when it returns off lease. On a purchase I look at it as the value I can sale it for when the equipment reaches its time of replacement. The one mistake many make on a lease is they care about the cost of the equipment and not the residual. The better residual you get on your equipment the better the payment will be and this all comes down to how well you take care of the equipment during the lease. The residual numbers can make a HUGE difference on your payment.

Factors

There are a lot of calculations in my program that I can’t share but there are a lot of one off things that can effect your equipment replacement and here are a few of those:

– Facility or golf course near the ocean.

– Equipment is stored outside in the elements.

– Level of maintenance kept on the equipment.

– How often the equipment is used.

– Pricing you receive on the equipment.

– How many years of warranty you negotiate.

All these factors have to be accounted for which makes doing something like this for the masses extremely complicated. I will begin putting reports together utilizing this system on consulting trips but I wanted to just put out there that purchasing equipment is something that should take us time to do. It’s a huge financial burden for a club and knowing what to expect and when makes everyone much more comfortable accepting it. The best thing we can do though is try to take the emotion out of it and let the data do the talking it’s always much easier that way.

You might also like

Toro DPA Triplex Reels

So I have this thing about making sure that every cutting unit we purchase has the “ability” to be fine tuned to absolute 0. While accomplishing this is very tough

Repair and Maintenance – Should it be one budget item?

I was meeting with a Superintendent friend of mine and we were discussing repair and maintenance budgets and what drives them. In a day and age where we are all trying

Another Good Friend Makes a Big Move

So I think I am going to name 2017 the year of big moves. There has been a lot of moving around this year in the world of Turf grass.

0 Comments

No Comments Yet!

You can be first to comment this post!